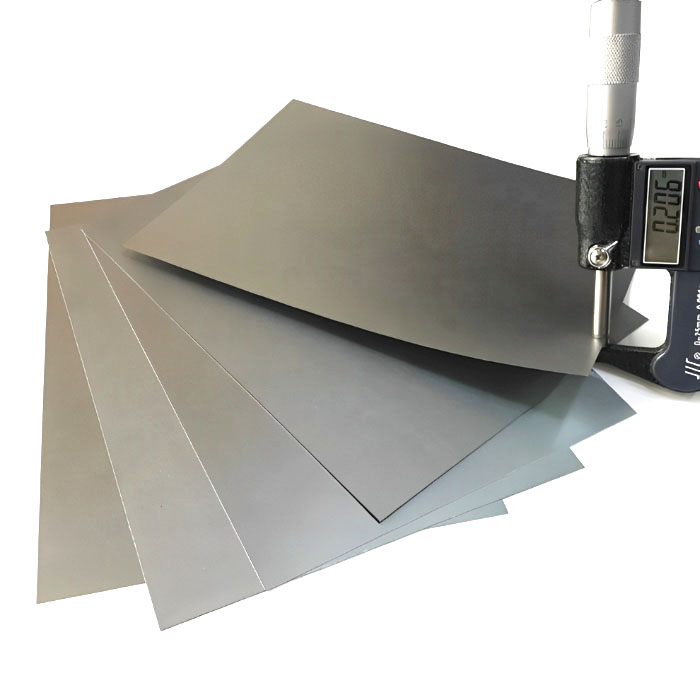

Tungsten Heavy Alloy (WNIFE) Rod

Tsanangudzo

Kuwanda kwe tungsten heavy alloy rod inotangira pa16.7g/cm3 kusvika 18.8g/cm3.Kuoma kwayo kwakakwirira kudarika dzimwe tsvimbo.Tungsten inorema alloy tsvimbo ine hunhu hwekupisa kwepamusoro uye kusagadzikana kwekuora.Uye zvakare, tungsten inorema alloy tsvimbo ine super high shock resistance uye mechanic plasticity.

Tungsten heavy alloy rods anowanzo shandiswa kugadzira nyundo mativi, radiation shielding, mauto edziviriro midziyo, welding tsvimbo uye extrusion modhi.Ichowo chimwe chezvinhu zvekugadzira zvombo uye zvombo.

Properties

| Density uye Kuoma Zvivakwa, ASTM B777 | |||

| Kirasi | Tungsten Purity,% | Density, g/cc | Kuoma, Rockwell"C", max |

| Kirasi 1 | 90 | 16.85-17.25 | 32 |

| Kirasi 2 | 92.5 | 17.15-17.85 | 33 |

| Kirasi 3 | 95 | 17.75-18.35 | 34 |

| Kirasi 4 | 97 | 18.25-18.85 | 35 |

| Kunyanya ye tungsten inowedzera hupfu hwakaita semhangura, nickel kana iron. | |||

| echanical Properties, ASTM B777 | ||||||

| Kirasi | Tungsten Purity,% | Ultimate Tensile Simba | Goho Simba pa 0.2% Off-set | Elongation,% | ||

| ksi | MPa | ksi | MPa | |||

| Kirasi 1 | 90 | 110 ksi | 758 MPa | 75 ksi | 517 MPa | 5% |

| Kirasi 2 | 92.5 | 110 ksi | 758 MPa | 75 ksi | 517 MPa | 5% |

| Kirasi 3 | 95 | 105 ksi | 724 MPa | 75 ksi | 517 MPa | 3% |

| Kirasi 4 | 97 | 100 ksi | 689 MPa | 75 ksi | 517 MPa | 2% |

| Kunyanya ye tungsten inowedzera hupfu hwakaita semhangura, nickel kana iron. | ||||||

Features

Kunze kwehupamhi hwepamusoro uye kunyura kwemwaranzi, zvakawanda zvakakosha zvivakwa zvine chekuita nekuomarara kwepamusoro uye kuramba zvakashandiswa muhuwandu hwekushandisa.Tungsten inorema alloy ndeye refractory simbi alloys ayo anopokana zvakanyanya nekupisa nekupfeka.Tungsten heavy alloy yainyanya kushandiswa kugadzira zvinhu zvaida kupfekwa kwepamusoro senge maturusi ekugadzira anosanganisira lathes nemadhayisi.

Inowana kuderedzwa kudiki muhunhu hwayo kunyangwe pakupisa kwepamusoro uye ine yakanakisa kupfeka kuramba.Naizvozvo, Tungsten alloys anoshandiswa kune machining maturusi senge lathes, milling muchina, nezvimwewo, uye kugadzira zvikamu zvemotokari zvakaita seinjini, transmissions, steering, nezvimwewo, izvo zvinobatsira mukuvandudza kweiyo machining.

Kuwedzera kwekushisa kwepasi

High thermal uye magetsi conductivity

High arc resistance

Kushandiswa kwakaderera

Applications

Tungsten heavy alloy yakanakisa mumashandisirwo anoda yakakwira kuita mukuora, density, machinability, uye neradiation kudzivirira.Naizvozvo, izvi zvinoita kuti ive yakakodzera kushandiswa mune yakatarwa simbi, migodhi, aerospace, uye maindasitiri ekurapa.