Yakachena Molybdenum Rod, Molybdenum Bar, Molybdenum Electrode

Zvinotsanangurwa

Type uye saizi:

| Type | Swaged Rods | Yakatwasanudzwa Tsvimbo mushure mekudhonzwa | Ground kana machined rods iripo |

| Size | Ф2.4~120mm | Ф0.8~3.2mm |

Kemikari Kuumbwa:

| Mo Content | Zvose Zviri Mukati Zvimwe Zvinhu | Chimwe nechimwe chikamu |

| ≥99.95% | ≤0.05% | ≤0.01% |

Applications

- Inokodzera kugadzira ion implantation parts.

- Yekugadzira magetsi emagetsi sosi zvikamu uye zvemagetsi vacuum zvikamu.

- Yekugadzira zvinhu zvekudziya uye zvikamu zvinodzikisira mumafuru ekupisa.

- Inoshandiswa mugirazi uye girazi fiber indasitiri, inogona kushanda hupenyu hurefu mune yakanyungudutswa girazi mvura pa1300 ℃.

- Inoshandiswa se electrode mumunda we isingawanzo pasi simbi indasitiri.

Unyanzvi

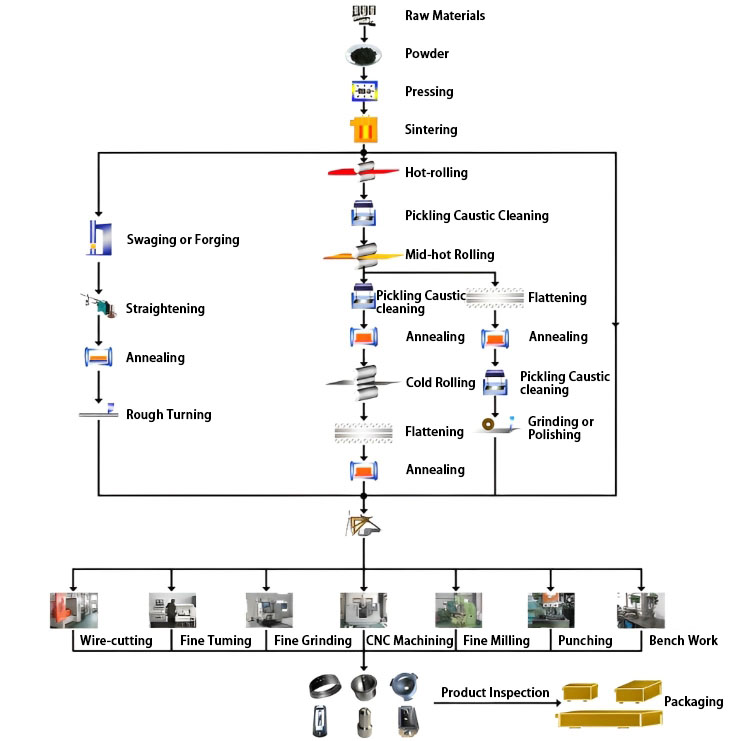

Raw Material:Kutanga kubva kune zvigadzirwa, isu tinosarudza emhando yepamusoro zvinhu, izvo zvinonyanya kutaridzika mukugadzikana uye kuenderana kwezvigadzirwa.Ziva mhando dzakasiyana dzezvigadzirwa uye nyora nhamba yebatch.Uye batch rimwe nerimwe rezvinhu zvakasvibirira rinofanira kuyerwa, kuongororwa uye kuchengetwa.Ita shuwa kuteedzera kwechigadzirwa chimwe nechimwe chakapedzwa uye nekuenderera mberi nekuvandudza kunaka kwechigadzirwa.

Upfu:Kudzora kwekuita kwekugaya kweZhaolinxin Metal zvigadzirwa kwakaringana, iine akati wandei akakura musanganiswa uye vibration mapuratifomu ekuona kuti zvinhu zviri mu pulverizing uye kusanganisa maitiro zvinogona kunyatsomutswa uye kugovaniswa zvakaenzana, kuitira kuti ive nechokwadi chekuenderana kwesangano remukati. zvigadzirwa.

Kudzvanya:Mukuita kwehupfu hwehupfu, hupfu hunotsikirirwa neisostatic yekutsikirira midziyo kuti iite chimiro chayo chemukati chakafanana uye chakakora.Zhaolixin ine yakakwana batch mold, uye zvakare ine isostatic yekutsikirira michina yekusangana nekugadzirwa kweakanyanya-makuru mabhechi ezvigadzirwa.

Sintering:Muhupfu hwesimbi, mushure mekunge simbi yehupfu yakaumbwa ne-isostatic pressing, inopisa pakupisa kwakadzika kudarika kunyunguduka kwezvikamu zvikuru kuita kuti zvikamu zvibatane, kuitira kuvandudza kushanda kwezvigadzirwa, izvo zvinonzi sintering.Mushure mekunge hupfu hwaumbwa, muviri wakaoma unowanikwa nekupisa imhando ye polycrystalline zvinhu.Iyo sintering maitiro inokanganisa zvakananga saizi yezviyo, saizi yepore uye chimiro chemuganho wezviyo uye kugovera mune microstructure, inova iyo yakakosha muitiro weupfu metallurgy.

Kugadzira:Iyo yekuumba maitiro inogona kuita kuti zvinhu zviwane yakakwirira density, zviri nani zvemichina zvivakwa, uye kuita basa mukusimbisa pamusoro.Kudzora kwakaringana kwechiyero chekugadzirisa uye tembiricha yekugadzira tungsten uye molybdenum zvinhu chinhu chakakosha pakuita kwepamusoro kweZhaolixin tungsten uye molybdenum zvinhu.Nzira yekugadzirisa yekushandisa muchina wekufogisa kuisa kumanikidza kune simbi isina kuvharwa kuti igadzirise mupurasitiki kuti iwane forging ine mamwe ma mechanic properties, imwe chimiro uye saizi.

Rolling:Iyo yekukungurutsa inoita kuti simbi yezvinhu iburitse inoenderera mberi deformation yepurasitiki pasi pekumanikidzwa kweiyo inotenderera roll, uye kuwana inodiwa chikamu chimiro uye zvivakwa.Iine tungsten yepamusoro uye molybdenum inotonhora uye inopisa yekutenderedza tekinoroji nemidziyo, kubva ku tungsten uye molybdenum simbi isina chinhu kusvika pakugadzirwa kwe tungsten uye molybdenum foil, Zhaolixinguarantees iwe yakawedzera kugadzirwa tekinoroji uye yepamusoro simbi zvivakwa.

Kupisa-Kubata:Mushure mekugadzira uye kutenderedza maitiro, zvinhu zvinoiswa pasi pekupisa kupisa maitiro kuti abvise zvachose kushushikana kwemukati kwemukati kwechinhu, kupa kutamba kune kuita kwezvinhu, uye kuita kuti zvinhu zvive nyore kune inotevera machining.Zhaolixin ine akawanda emavira evacuum uye kupisa kupisa hydrogen mavira kuti asangane nekukasira kuendesa kwemazhinji ekugadzira maodha.

Machining:Zvinhu zveZhaolixin zvakagadziriswa kupisa kwekupisa, uye zvakagadziridzwa muhukuru hwakasiyana-siyana nekugadzira michina yakadai sekushandura, kugaya, kucheka, kugaya, nezvimwewo, uye inovimbisa kuti sangano remukati re tungsten uye molybdenum zvinhu zvakasimba, zvisina kushungurudzika. uye isina gomba, iyo inogona kusangana nezvinodiwa nevatengi.

Hunhu Hwaro:Kuongororwa kwemhando uye kutonga kuchaitwa kubva kune zvigadzirwa uye kune yega yega nhanho yekugadzira, kuitira kuti urambe uine chokwadi chemhando yechigadzirwa chimwe nechimwe.Panguva imwecheteyo, kana zvigadzirwa zvakapedzwa zvinounzwa kubva mudura, kutaridzika, ukuru uye kurongeka kwemukati kwezvinhu zvinoedzwa chimwe nechimwe.Nokudaro, kugadzikana uye kuwirirana kwezvigadzirwa zvinonyanya kuoneka.